Network communication

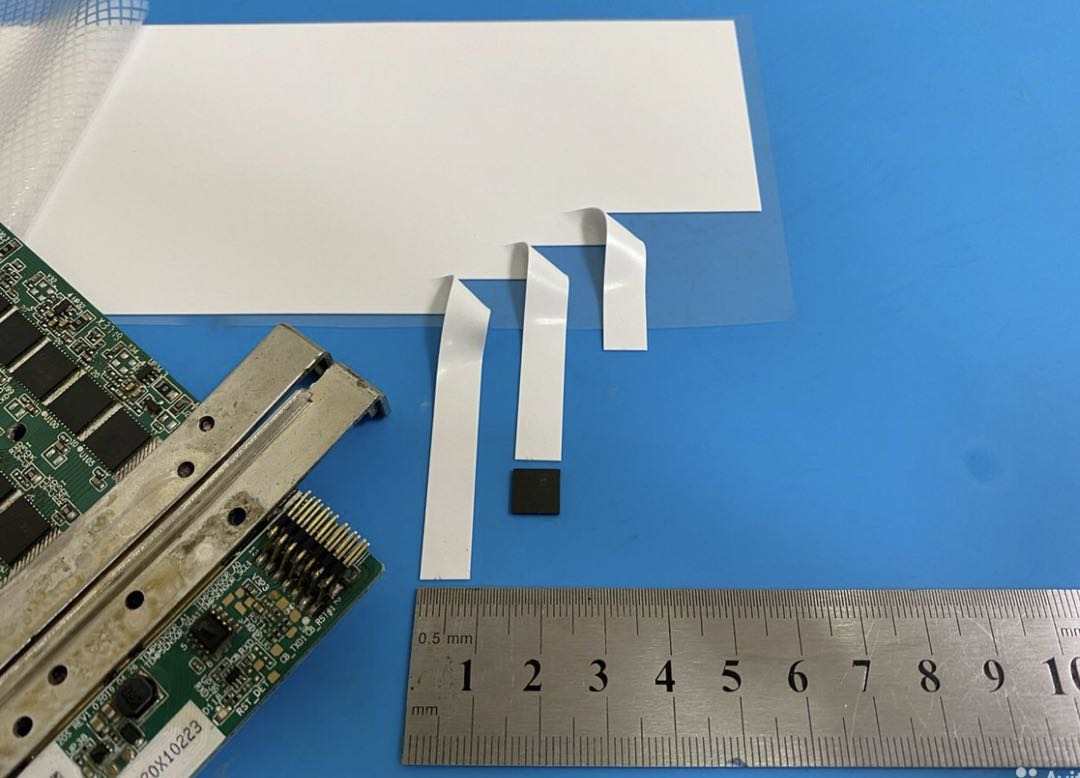

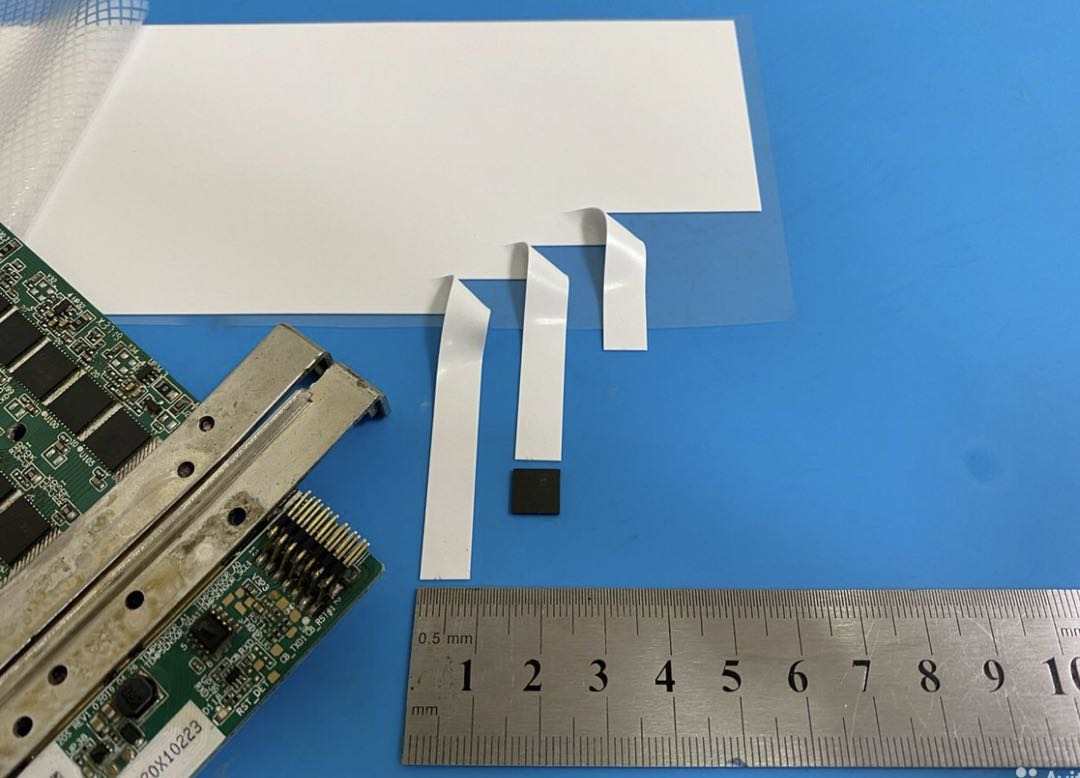

Thermal conductive silicone sheets are divided into ordinary thermal conductive silicone sheets, highly adhesive thermal conductive silicone sheets, back silicone adhesive tape thermal conductive silicone sheets, and those with glass fiber in the middle. These are specially designed for heat transfer through gaps and are produced for this purpose. They can fill the gaps and complete the heat transfer between the heating part and the cooling part. At the same time, they also have functions such as insulation, vibration reduction, and sealing, which can meet the design requirements for miniaturization and ultra-thinness of equipment. They are of good processability and usability, with a wide range of thickness applicability, and are a good thermal filling material. Thermal silicone sheets are used in many fields. 1. Application in the LED industry: Thermal conductive silicone sheets are used between the aluminum substrate and the heat sink, as well as between the aluminum substrate and the casing. II. Power Supply Industry: Utilizing heat conduction between MOS transistors, transformers (or capacitors/PFC inductors) and heat sinks or enclosures III. Communication Industry: Thermal conduction and heat dissipation for TD products between the mainboard IC and the heat sink or casing, as well as between the set-top box DC-DC IC and the casing. IV. Applications in the automotive electronics industry: The automotive electronics industry (such as xenon lamp ballasts, audio systems, in-vehicle products, etc.) can all utilize thermal conductive silicone sheets. V. Application of PDP/LED TVs: Heat Conduction Between Power Amplifier IC, Image IC and Heat Sink (Enclosure) VI. Household Appliance Industry: Microwave Ovens/Air Conditioners (Motor Power IC and Outer Shell)/Induction Stoves (Thermistor and Heat Sink) Correct Installation Steps for Thermal Silicone Sheets Keep the surface of the thermal conductive silicone sheet clean. 2. When removing the thermal silicone sheets, for the larger ones, they should be grasped from the middle part. There is no specific requirement for the smaller sheets. 3. Hold the sheet material with your left hand and remove the release film from one side with your right hand. Do not remove both sides of the protective film at the same time. This reduces the number and area of direct contact with the thermal conductive silicone sheet, and ensures that the self-adhesiveness and thermal conductivity of the silicone sheet are not damaged. 4. Remove the protective film from the side facing the radiator. Align the thermal silicone sheet with the radiator first. When slowly lowering the thermal silicone sheet, be careful to avoid the formation of bubbles. 5. Remove the protective film on the other side and insert it into the heat sink. When removing the protective film on the back, do it gently to avoid damaging or pulling out the thermal conductive silicone sheet. 6. After tightening or applying strong adhesive thermal silicone sheets, apply a certain pressure to the heat sink and store it for a period of time to ensure that the thermal silicone sheets are firmly fixed.

Thermal conductive silicone sheets are divided into ordinary thermal conductive silicone sheets, highly adhesive thermal conductive silicone sheets, back silicone adhesive tape thermal conductive silicone sheets, and those with glass fiber in the middle. These are specially designed for heat transfer through gaps and are produced for this purpose. They can fill the gaps and complete the heat transfer between the heating part and the cooling part. At the same time, they also have functions such as insulation, vibration reduction, and sealing, which can meet the design requirements for miniaturization and ultra-thinness of equipment. They are of good processability and usability, with a wide range of thickness applicability, and are a good thermal filling material. Thermal silicone sheets are used in many fields. 1. Application in the LED industry: Thermal conductive silicone sheets are used between the aluminum substrate and the heat sink, as well as between the aluminum substrate and the casing. II. Power Supply Industry: Utilizing heat conduction between MOS transistors, transformers (or capacitors/PFC inductors) and heat sinks or enclosures III. Communication Industry: Thermal conduction and heat dissipation for TD products between the mainboard IC and the heat sink or casing, as well as between the set-top box DC-DC IC and the casing. IV. Applications in the automotive electronics industry: The automotive electronics industry (such as xenon lamp ballasts, audio systems, in-vehicle products, etc.) can all utilize thermal conductive silicone sheets. V. Application of PDP/LED TVs: Heat Conduction Between Power Amplifier IC, Image IC and Heat Sink (Enclosure) VI. Household Appliance Industry: Microwave Ovens/Air Conditioners (Motor Power IC and Outer Shell)/Induction Stoves (Thermistor and Heat Sink) Correct Installation Steps for Thermal Silicone Sheets Keep the surface of the thermal conductive silicone sheet clean. 2. When removing the thermal silicone sheets, for the larger ones, they should be grasped from the middle part. There is no specific requirement for the smaller sheets. 3. Hold the sheet material with your left hand and remove the release film from one side with your right hand. Do not remove both sides of the protective film at the same time. This reduces the number and area of direct contact with the thermal conductive silicone sheet, and ensures that the self-adhesiveness and thermal conductivity of the silicone sheet are not damaged. 4. Remove the protective film from the side facing the radiator. Align the thermal silicone sheet with the radiator first. When slowly lowering the thermal silicone sheet, be careful to avoid the formation of bubbles. 5. Remove the protective film on the other side and insert it into the heat sink. When removing the protective film on the back, do it gently to avoid damaging or pulling out the thermal conductive silicone sheet. 6. After tightening or applying strong adhesive thermal silicone sheets, apply a certain pressure to the heat sink and store it for a period of time to ensure that the thermal silicone sheets are firmly fixed. Thermal conductive silicone sheets are divided into ordinary thermal conductive silicone sheets, highly adhesive thermal conductive silicone sheets, back silicone adhesive tape thermal conductive silicone sheets, and those with glass fiber in the middle. These are specially designed for heat transfer through gaps and are produced for this purpose. They can fill the gaps and complete the heat transfer between the heating part and the cooling part. At the same time, they also have functions such as insulation, vibration reduction, and sealing, which can meet the design requirements for miniaturization and ultra-thinness of equipment. They are of good processability and usability, with a wide range of thickness applicability, and are a good thermal filling material. Thermal silicone sheets are used in many fields. 1. Application in the LED industry: Thermal conductive silicone sheets are used between the aluminum substrate and the heat sink, as well as between the aluminum substrate and the casing. II. Power Supply Industry: Utilizing heat conduction between MOS transistors, transformers (or capacitors/PFC inductors) and heat sinks or enclosures III. Communication Industry: Thermal conduction and heat dissipation for TD products between the mainboard IC and the heat sink or casing, as well as between the set-top box DC-DC IC and the casing. IV. Applications in the automotive electronics industry: The automotive electronics industry (such as xenon lamp ballasts, audio systems, in-vehicle products, etc.) can all utilize thermal conductive silicone sheets. V. Application of PDP/LED TVs: Heat Conduction Between Power Amplifier IC, Image IC and Heat Sink (Enclosure) VI. Household Appliance Industry: Microwave Ovens/Air Conditioners (Motor Power IC and Outer Shell)/Induction Stoves (Thermistor and Heat Sink) Correct Installation Steps for Thermal Silicone Sheets Keep the surface of the thermal conductive silicone sheet clean. 2. When removing the thermal silicone sheets, for the larger ones, they should be grasped from the middle part. There is no specific requirement for the smaller sheets. 3. Hold the sheet material with your left hand and remove the release film from one side with your right hand. Do not remove both sides of the protective film at the same time. This reduces the number and area of direct contact with the thermal conductive silicone sheet, and ensures that the self-adhesiveness and thermal conductivity of the silicone sheet are not damaged. 4. Remove the protective film from the side facing the radiator. Align the thermal silicone sheet with the radiator first. When slowly lowering the thermal silicone sheet, be careful to avoid the formation of bubbles. 5. Remove the protective film on the other side and insert it into the heat sink. When removing the protective film on the back, do it gently to avoid damaging or pulling out the thermal conductive silicone sheet. 6. After tightening or applying strong adhesive thermal silicone sheets, apply a certain pressure to the heat sink and store it for a period of time to ensure that the thermal silicone sheets are firmly fixed.

Thermal conductive silicone sheets are divided into ordinary thermal conductive silicone sheets, highly adhesive thermal conductive silicone sheets, back silicone adhesive tape thermal conductive silicone sheets, and those with glass fiber in the middle. These are specially designed for heat transfer through gaps and are produced for this purpose. They can fill the gaps and complete the heat transfer between the heating part and the cooling part. At the same time, they also have functions such as insulation, vibration reduction, and sealing, which can meet the design requirements for miniaturization and ultra-thinness of equipment. They are of good processability and usability, with a wide range of thickness applicability, and are a good thermal filling material. Thermal silicone sheets are used in many fields. 1. Application in the LED industry: Thermal conductive silicone sheets are used between the aluminum substrate and the heat sink, as well as between the aluminum substrate and the casing. II. Power Supply Industry: Utilizing heat conduction between MOS transistors, transformers (or capacitors/PFC inductors) and heat sinks or enclosures III. Communication Industry: Thermal conduction and heat dissipation for TD products between the mainboard IC and the heat sink or casing, as well as between the set-top box DC-DC IC and the casing. IV. Applications in the automotive electronics industry: The automotive electronics industry (such as xenon lamp ballasts, audio systems, in-vehicle products, etc.) can all utilize thermal conductive silicone sheets. V. Application of PDP/LED TVs: Heat Conduction Between Power Amplifier IC, Image IC and Heat Sink (Enclosure) VI. Household Appliance Industry: Microwave Ovens/Air Conditioners (Motor Power IC and Outer Shell)/Induction Stoves (Thermistor and Heat Sink) Correct Installation Steps for Thermal Silicone Sheets Keep the surface of the thermal conductive silicone sheet clean. 2. When removing the thermal silicone sheets, for the larger ones, they should be grasped from the middle part. There is no specific requirement for the smaller sheets. 3. Hold the sheet material with your left hand and remove the release film from one side with your right hand. Do not remove both sides of the protective film at the same time. This reduces the number and area of direct contact with the thermal conductive silicone sheet, and ensures that the self-adhesiveness and thermal conductivity of the silicone sheet are not damaged. 4. Remove the protective film from the side facing the radiator. Align the thermal silicone sheet with the radiator first. When slowly lowering the thermal silicone sheet, be careful to avoid the formation of bubbles. 5. Remove the protective film on the other side and insert it into the heat sink. When removing the protective film on the back, do it gently to avoid damaging or pulling out the thermal conductive silicone sheet. 6. After tightening or applying strong adhesive thermal silicone sheets, apply a certain pressure to the heat sink and store it for a period of time to ensure that the thermal silicone sheets are firmly fixed.